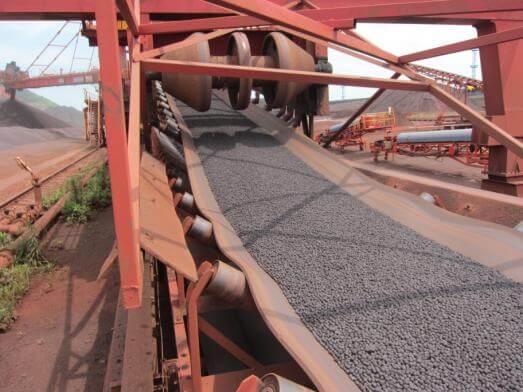

Iron ore and concentrate inspection

Iron ore and concentrate inspection ensures quality control at different stages of the logistics chain, minimizing trade risks associated with cargo specification deviations, discrepancies in quantity, or incomplete documentation for export and import operations.

CISS GROUP provides iron ore and concentrate inspection services for major metallurgical holdings, processing plants, scrap steel suppliers, and international metal trading companies. These services cover procurement, storage, loading, and unloading at intermediate warehouses and global ports.

Iron ore and concentrate require strict transportation conditions. Due to their high value, transportation poses significant commercial risks for all parties involved. Weight control, sampling, and laboratory quality testing in compliance with standards are crucial during handling.

Accredited inspectors and laboratory technicians from CISS GROUP conduct inspections at every stage of the supply chain.

The main stages of iron ore and concentrate inspection:

Incoming and outgoing inspection

This stage includes procurement and delivery of iron ore and concentrate to warehouses, ports, or removal from storage facilities. CISS GROUP inspectors assess storage conditions, verify cargo weight, and take samples. Before sampling, a visual assessment determines uniformity in size and moisture content.

Container and vessel hold cleanliness inspection

A visual inspection of containers and empty holds ensures cleanliness and suitability for transportation. Inspectors examine internal surfaces, assess the integrity of locks, hinges, and fasteners, and check rubber seals on container doors and hold covers.

Loading process monitoring and sampling

During loading, inspectors oversee operations, confirm gross and net weight, and conduct weight checks using the draft survey method. They monitor the fumigation process, visually assess cargo quality, and collect samples according to established procedures. At the end of loading, inspectors seal containers or holds and document findings in real-time reports. CISS GROUP provides 24/7 inspection and sampling services.

Laboratory analysis of iron ore and concentrate quality

Quality testing is conducted exclusively in accredited laboratories following international contractual standards. Key quality indicators include mass fractions of total iron, iron oxide, metallic iron, moisture, hygroscopic moisture, arsenic, phosphorus, sulfur, copper, zinc, and lead. Additional tests determine particle size distribution, uniformity in chemical and size composition, immersion characteristics, cold compressive strength, and abrasion index.

Composite samples represent entire cargo lots, while individual batch tests determine total iron and moisture content. The mineralogical type of iron ore and concentrate is identified based on quantitative ratios of iron ore minerals. Analyses include macroscopic and microscopic examinations:

- Macroscopic analysis determines mineral composition, macrostructure, color, luster, hardness, porosity, oxidation, leaching, cementation, tectonic disturbances, and the presence of veins.

- Microscopic analysis identifies mineral composition, structural and genetic relationships, grain size distribution, inclusion characteristics, and mineral structural changes using a polarizing microscope. Mineral ratios and grain sizes are also calculated.

Photo and video reporting

Each inspection stage is documented through photographs and videos, timestamped for accuracy. Upon completion, CISS GROUP provides a detailed photo report covering all inspection and control stages.

Certification

Following the inspection, final certificates or reports are issued. Clients can verify document authenticity via a unique QR code, granting access to digital certificates on the CISS GROUP website. Digital cryptographic signatures ensure security and reliability.

Digitally signed certificates are often required by banks for trade financing verification, particularly in letter-of-credit transactions.

Send request