Citrus inspection

Citrus inspection is a structured quality control process conducted at various stages of the logistics chain. It mitigates trade risks associated with non-compliance to product specifications, quantity discrepancies, or incomplete documentation during international citrus export and import operations.

Citrus fruits include oranges, lemons, tangerines, grapefruits, citrons, pomelos, kumquats, limes, and others.

CISS GROUP delivers professional citrus inspection services to leading agribusinesses and international trading companies at all stages of the production and logistics chain. Inspections are carried out at intermediate storage facilities, cold warehouses, processing plants, and ports worldwide.

Citrus fruits are primarily exported for fresh consumption and are classified as highly perishable goods. For this reason, it is essential to maintain strict temperature control throughout transportation and storage. The use of refrigerated containers is considered the most efficient solution, as it ensures optimal temperature conditions and helps preserve product appearance and quality during long-distance shipments.

Scope of citrus inspection

- Tally verification

- Weight control

- Sampling

- Calibration by size

- Classification by color

- Detection of skin defects using non-visible light wavelengths

- Laboratory testing for pesticide residues – due to extensive use of chemicals during citrus growth and post-harvest treatment, analysis for pesticide residues is essential to ensure compliance with international food safety standards.

CISS GROUP’s certified inspectors and laboratory specialists carry out citrus inspections at any stage of the global supply chain.

The main stages of checking citrus fruits:

Incoming and outgoing inspection

Inspection is performed during delivery to cold storage rooms, fruit handling bases, or refrigerated containers. Inspectors assess the condition of storage facilities and verify that the product is intact, dry, pest-free, and not mixed, damaged, overripe, moldy, wet, frozen, or carrying foreign odors or contaminants.

Container cleanliness and suitability check

This includes a detailed visual inspection of refrigerated containers to confirm their cleanliness and operational readiness. Inspectors check cooling systems, internal surfaces, temperature sensors, locks, hinges, and rubber seals to ensure the container is fit for citrus transport.

Loading supervision and sampling

During loading, inspectors monitor:

- Packaging and labeling of citrus fruit

- Number of fruits per container or box

- Gross and net weight control

- Temperature consistency, especially during seasonal transitions with large fluctuations (up to 30–40°C)

They also assess fruit color and surface condition, ensuring product freshness and compliance with standards. After loading is complete, inspectors seal the containers and record all data in the inspection report.

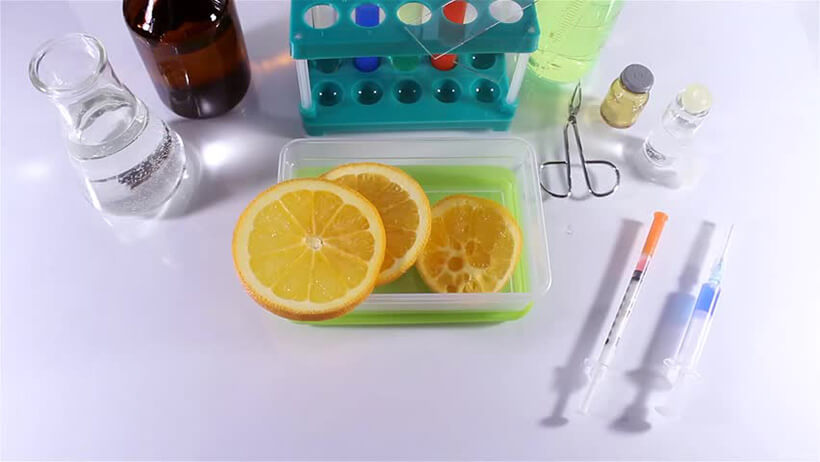

Laboratory analysis of citrus fruits

All laboratory tests are conducted exclusively in accredited laboratories in accordance with recognized international quality and safety standards. Key quality indicators include:

- External appearance

- Color and uniformity

- Presence of mold or damage

- Aroma and flavor

- Sugar content (Brix level)

Additional laboratory testing may include detection of:

- Toxic elements: mercury, arsenic, lead, cadmium

- Pesticide residues

- Radionuclide contamination

Upon request, organoleptic evaluation (taste, aroma, mouthfeel) is performed for each lot during inspection.

Photo and video documentation

CISS GROUP inspectors document each stage of the inspection using timestamped photographs and video recordings. At the end of the inspection, clients receive a detailed photo report covering the entire control process.

Certificates and digital authentication

Upon completion of the citrus inspection, official certificates and inspection reports are issued. Each document includes a unique QR code, which provides direct access to a secure digital archive hosted on the CISS GROUP website, where authenticated PDF copies are stored.

All certificates are digitally signed using cryptographic technology, ensuring document authenticity, security, and tamper-proof verification.

These verified documents are frequently required by banks and financial institutions to validate the transparency and integrity of trade operations during letter of credit and trade finance processes.

Send request