Banana inspection

Banana inspection is a structured quality control process carried out at various stages of the logistics chain. It minimizes key trade risks associated with non-compliance with product specifications, discrepancies in quantity, or incomplete documentation during banana export and import operations.

CISS GROUP offers professional banana inspection services for major agribusinesses and international trading companies. Inspections are performed at every stage of the production and transportation chain, including intermediate storage facilities, cold warehouses, packing stations, and seaports worldwide.

As bananas are primarily exported for fresh consumption, they are classified as perishable products. Strict temperature control is essential to maintain product integrity during long-distance transportation. Due to the high ethylene release rate of bananas, proper storage conditions are critical. Bananas must be stored separately from other fruits, vegetables, and berries to avoid cross-contamination and spoilage.

Scope of banana inspection

- Tally verification

- Marking and labeling check

- Packaging condition assessment

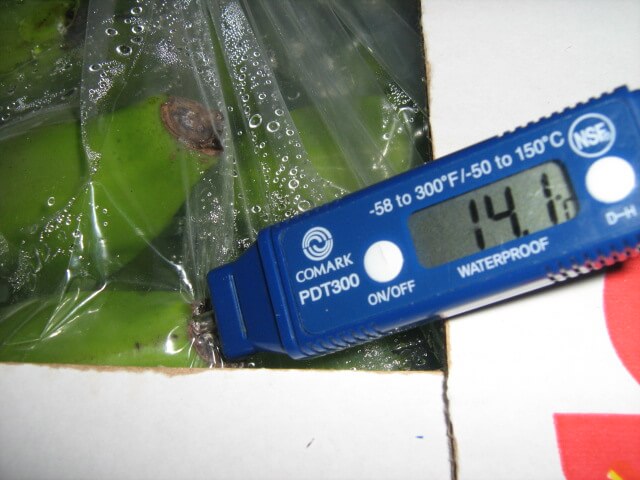

- Product temperature monitoring

Pulp temperature must be carefully measured and documented during transit or upon arrival, as it directly impacts freshness and shelf life.

Size measurement of bananas

Size control is applied to individual fruits (fingers), regardless of whether they are packed in clusters or hands. Measurements include:

- Length – measured along the outer curve from end to end

- Fullness – diameter of the fruit to determine maturity and consistency

Measurements are conducted using a flexible ruler or calibrated devices to ensure accurate sizing across the shipment.

Sampling procedures

Accurate certification depends on obtaining representative samples. All portions of the load must be equally considered during sampling, regardless of accessibility. If the entire lot is not accessible, certification applies only to the inspected portion. Proper sampling ensures a fair evaluation of product quality.

Quality and condition factors

- Bruising

- Chilling or freezing damage

- Discoloration

- Overheating

- Ripeness stage

- Shape irregularities

- Presence of decay

The main stages of bananas inspection:

Incoming and outgoing banana inspection

Conducted during delivery to cold storage chambers, fruit handling bases, or refrigerated containers. Inspectors evaluate facility suitability and cargo condition. The product must be clean, dry, intact, not mixed with other goods, and free of mold, pests, or off-odors.

Container cleanliness and suitability check

A comprehensive visual inspection of refrigerated containers is conducted to verify cleanliness and suitability. Internal surfaces, seals, cooling systems, temperature sensors, and locking mechanisms are checked for proper function.

Loading supervision and sampling

During loading, inspectors monitor:

- Packaging quality

- Labeling consistency

- Fruit count per box

- Gross and net weights

- Cargo color and surface condition

- Temperature control (especially critical during autumn-winter shipping, when external temperatures may fluctuate by 30–40°C)

Upon completion, containers are sealed and detailed reports are submitted to the client with real-time access.

CISS GROUP provides round-the-clock inspection and sampling services upon request.

Laboratory testing of banana quality

Laboratory testing is performed exclusively in ISO-accredited laboratories in full compliance with international food safety standards.

Standard quality indicators include:

- Appearance

- Color uniformity

- Mold presence and physical damage

- Odor and taste

- Sugar content (Brix level)

Advanced testing includes:

- Toxic element screening: mercury, arsenic, lead, cadmium

- Pesticide residue analysis

- Radionuclide content

- Microbiological evaluation

At the client’s request, organoleptic testing (texture, flavor, and aroma) is also performed for each lot.

Photo and video documentation

Each inspection stage is documented with timestamped photos and videos. A detailed visual report is prepared for clients, ensuring transparency, traceability, and full visibility of all control measures taken.

Certification and digital verification

Following the inspection, CISS GROUP issues official inspection certificates and reports. Each certificate contains a unique QR code linking to a secure digital archive where digitally signed PDF documents are stored.

All certificates are protected by cryptographic digital signatures, ensuring their authenticity and integrity. These documents are frequently used by banks and financial institutions to validate trade transactions supported by letters of credit and other financing tools.

Send request